SHEET METAL ROLL FORMING

Introduction

The demand for sheet metal products with various geometries, functionalities, performance properties such as elongation, yield-point, anisotropy, grain size, residual stresses, spring back, and wear has significantly increased in the recent few years. However, in order to achieve lower production cost, higher quality and keeping competitive in in cutting edge market, traditional ways of trial and error have to be assisted and enhanced in the early stages of design using the revolutionary capabilities of simulation.

Factors affecting the forming process

During the forming processes, the interaction and interplay among different factors including die assembly and components, billet (block, bar, cylinder, or sheet) material, its microstructure as well as mechanical properties and the designed process route, process parameter configuration including working temperature, deformation amount, and strain rate all affect the quality of the final product.

Main challenges to defect free products

During the sheet metal forming process, the sheet undergoes different operations such as shearing, drawing, bending, and forming. The driving forces for all of these processes is the plastic deformation of material. However, the changes happens not only for the geometry, but also for the microstructure of the material to meet the required characteristics of both geometry; in terms of shape, surface topography structure, and dimensions, and microstructure; in terms of phase transformation, movement of structural defects such as grain boundaries, point vacancies, line, screw dislocations.

In addition, if the working the stress exceeds the strength of the material, ductile fracture, which is considered to be one of the main defects to be considered in cold working process and tooling design, would happen in the deformation process which could be detrimental in some cases. Furthermore, the undesirable stresses, induced in cold forming process, could affect both mechanical and mechanical properties and in turn the quality of the product.

Industry overriding issues

In every manufacturing in general, and forming in particular, there are three overriding issues that drive the whole process and make it successful or not which are the productivity, product cost, product quality. All of them are essential to achieve certain profit margin with quite severe competition in both domestic and global markets. Therefore, the pressing and bottleneck questions that every business owner or manager are trying to answer are:

- How to improve productivity?

- How to cut production cost?

- How to shorten time to market?

- How to enhance product quality?

- How to reduce the trial and error times in the workshop before mass production?

- How to meet the international standards?

Therefore, the traditional ways of design and manufacturing should be enhanced by performing preliminary assessment to the whole process via simulation tool in order to support the decision-making and obtain solutions at different design stages based on:

- Geometry

- Dimension

- Quality standards requirements

- Process route determination

- Process parameter configuration

- Design of tooling assembly

- Structure and detailed components

Today’s market challenges

Simulations enabled the design and development of sheet metal formed products to approach their goals in significantly promising way that helps to figure out the interaction and interplay of the designs in different categories and optimize the whole forming system.

On the other hand, in today’s highly competitive markets, understanding the structure of a product is essential to improve the process to find the correct pricing strategy. In other words, the production cycle of sheet metal forming involves several phases as indicated in figure [1]:

Figure 1 Sheet roll forming phases:

Estimation for the major expenses:

In figure [2], it can be seen that the forming and machining phases represent around 14% of the total cost of the product while the raw material represent 86% of the total cost. Thus, any reduction in the material being used during trial and error process, scrape rate, energy used for mills can significantly reduce the overall production costs.

International standards compliance

In the current market, where competition is fierce and resources are scare, complying with standards can improve the quality, and consistency of the product. The ability to purchase material with defined properties and a recognized level of quality reduces the risk of incompatibility or failure, and ensures that products perform as intended. Businesses can be assured that metals and components supplied by different companies will be mutually compatible.

Using standards also helps businesses demonstrate to regulators and customers that their products and services meet defined safety, quality, and environmental standards. By meeting the legislative and regulatory requirements enables companies to develop competitive manufacturing capabilities and expand their market with various industries such as oil & gas, automotive, aerospace, and military.

For instance, in order to fabricate non-alloy steel tubes suitable for welding and threading, the EN 10021:1993, and EN 10266:2003 have to be followed. The standard require to do some mechanical and thermal tests in order to approve the product.

Simulation = Cost savings & Standards compliance!

Cost reduction

Simulation has now gained the industrial stage, and it has become possible to simulate metal deformation and calculate stress and strain states for complex processes. By using simulations, the tool development and product trial and error time has been reduced by approximately 80% and this would be reflected to both time and cost reduction as follows:

- Time reduction

Early evaluation of formability

Reduction in the development times

Reduction of the trial and error

Quick response to needed modifications

- Cost reduction

Lower labor cost

Lower product costs

Reduction of the die costs and their maintenance

Increase the reliability

- Increase of product quality

Optimal selection of the workpiece material

Production of more complicated parts

Know-how accumulation for new materials

Press repeatability

- Material cost reduction

Saving from 5-25% of material cost

More than 70% improvement for the productivity

90% of the forming feasibility issues can be determined within few minutes and hours.

Standards compliance

Simulation can help evaluate and all the mechanical, thermal, and microstructure properties of material at each forming stage to meet the international standards, as indicated in EN10021:1993, and EN10266:2003, in terms of:

- Tensile tests

Tensile strength

Upper yield strength

Percentage of elongation

- Bend test

Different bend angle

Different metal grades and compositions

Different bending orientation

- Weldment tests

Quality

Cracks

Strength

Porosity

Complex process requires powerful solver

Complexity of the process

The complexity of sheet metal process in both the modeling and simulation can be broken down as follows:

Metal forming is a Multiphysics process where mechanical, thermal, and material field are coupled.

The design of the deformed parts to be the best is quite challenging as it affects the process determination, tooling structure, component design, service life, material and energy consumption that are directly translated into overriding costs

The relations between process route and process parameters (forming temperature, deformation velocity, deformation amount, lubrication condition) is quite complex and the sensitivity and combinations between all the driving parameters should be investigated properly in order to achieve the best design.

For the same geometries, the internal microstructure, defamation, material flow distribution, defect formation can be quite different from one combination of process to another. Thus, it’s not a trivial issue at all.

Die geometry, wear and service life affect the stresses within the workpiece and the die. Therefore, the die radius, taper angle, clearance, fillet radius, strength, function, and performance should be addressed.

Defect formation, prediction and avoidance due to applied load should be investigated to predict the fracture which cover crack initiation, formation and growth.

Simufact is a well-developed non-linear solver

Simufact software solutions cover a large number of metal working and metal processing production processes.

Simufact covers wide range of forming processes

Simufact Forming takes into account all areas of forming technology and therefore ensures a highly realistic simulation of the processes by considering:

The kinematics of the machine, no matter what kind, and no matter how complex

The behavior of the material, elasticity, plasticity, hardening and softening, as well as effects that depend on temperature and speed

The friction and contact between the tooling and the workpiece

The thermodynamics of the process, workpiece heating, heat transfer into the dies and into the environment, temperature increase due to forming energy, friction heat, etc.

The complexity and precision of the simulation model can be increased, if necessary. For example, single pre-defined model parameters can be replaced by measured values.

Dual solver for realistic results

Mature solver technologies, with the highest precision of reproducing the relevant physical effects, contribute substantially to the high quality of Simufact Forming’s simulation results. Simufact Forming offers two numerical calculation methods for the simulation that complement each other:

A finite-volume solver, based on MSC´s explicit Dytran solver, is used for the especially efficient simulation of warm and hot forging processes with significant burr formation

A finite-elements solver, based on MSC´s implicit Marc solver for nonlinear applications, is used to simulate all process types.

Both solvers have continuously been developed by MSC over the past decades and make it possible to reproduce the complex, nonlinear physics of forming processes with the highest precision. These solver technologies offer the utmost precision in result by the use thermo-mechanical, elasto-plastic element formulation.

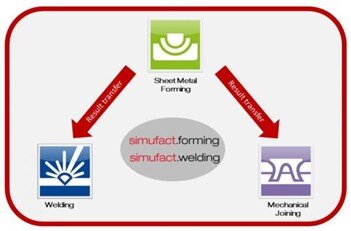

Entire process chains can be integrated together

The application module’s functions allow for the simulation of single manufacturing steps. However, the modules can also be combined spanning applications and products in order to connect the various manufacturing steps to entire process chains as shown in figure [3]:

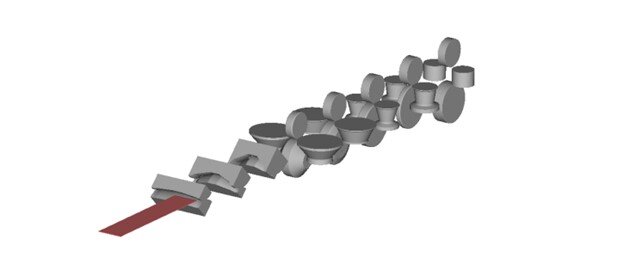

In figure [4], a showcase roll forming process with 8 forming stages is shown, in which a sheet contour shall be closed at the end of the process. The simulation is carried out in 3D. The geometries of the rolls are imported through the dxf interface, especially developed for roll forming simulations.

The blank is initially meshed on the basis of the (expected) final geometry, accounting for areas subject to high plastic deformation which typically are meshed with a finer mesh.

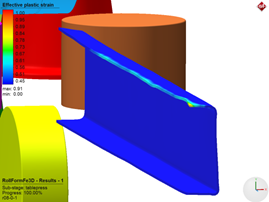

Figure 5a: Effective plastic strain

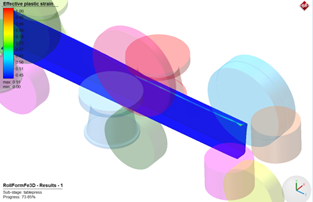

Figure 5b: Effective plastic strain

Figure 6: Thickness distribution

Figure 7: Cross section of the blank in the sixth roll pass

Figure 8: Effective stress

Figure 9: Yield stress

The peak of the effective plastic strain at the edge of the blank is generated in the seventh rolling pass. It is up to the experienced user to decide if this peak is disadvantageous for the process or product properties and to decide if and which countermeasures are to be taken.

References

- http://www.world-aluminium.org/statistics/#linegraph

- https://www.wenzelmetalspinning.com/steel-vs-aluminum.html

- https://www.dynamore.de/de/download/papers/forum08/dokumente/A-I-06.pdf

- https://www.linkedin.com/pulse/how-calculate-total-manufacturing-cost-sheet-metal-products-dallan

- https://books.google.com.eg/books?id=s6Xw2CcXElEC&pg=PA51&lpg=PA51&dq=the+cost+reduction+of+metal+forming&source=bl&ots=s_7B6Z1USs&sig=ACfU3U10c9B2qHSXlZxokYwWX6B9AXnlyQ&hl=en&sa=X&ved=2ahUKEwjt1_SU4cDhAhWUo3EKHcW6B1I4FBDoATAHegQICRAB#v=onepage&q=the%20cost%20reduction%20of%20metal%20forming&f=false

- https://continentalsteel.com//nas/content/live/continentalst/wp-content/uploads/Metal-Standards-and-Their-Importance-eBook.pdf